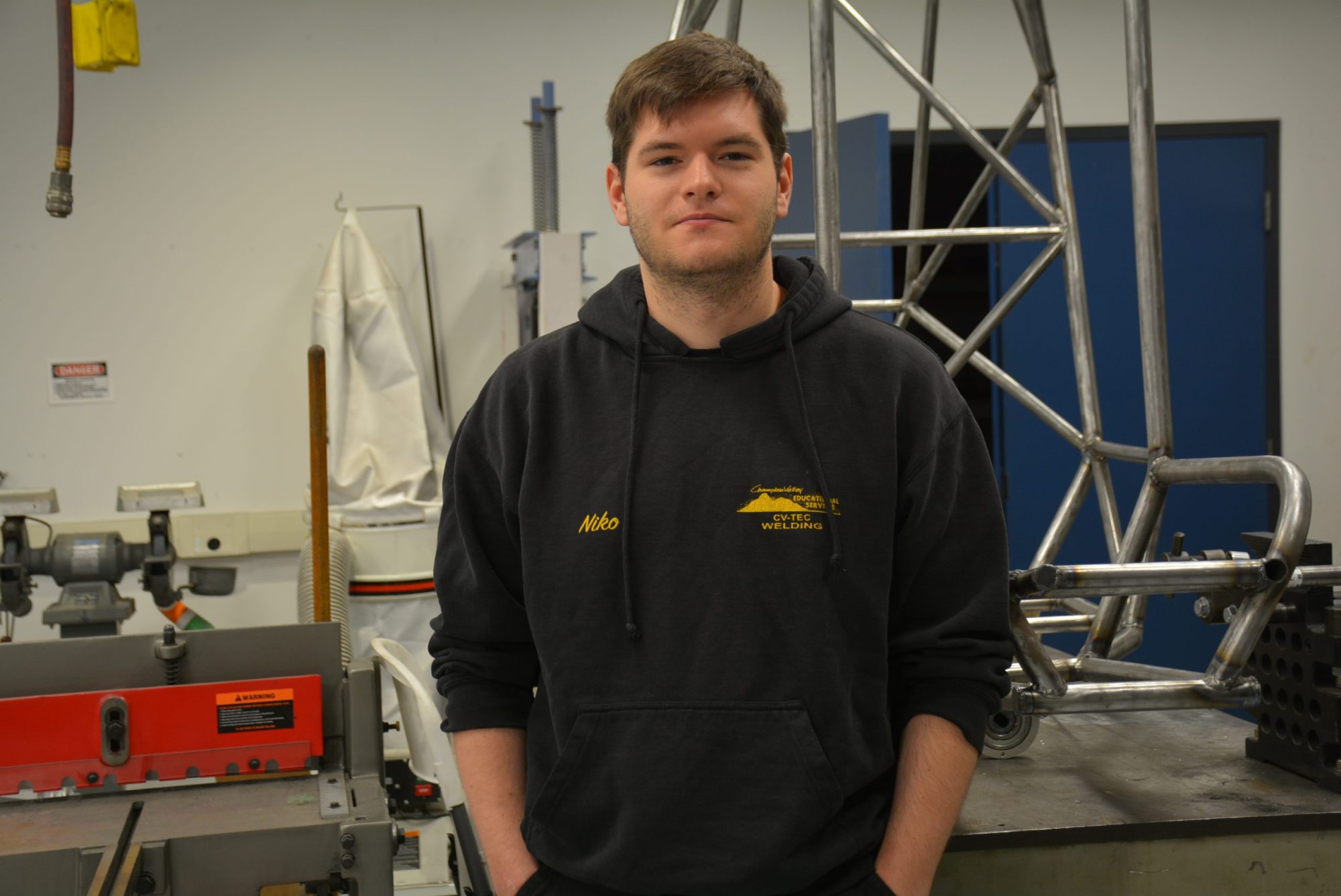

Some people go their entire lives not knowing exactly what they want to do, but SUNY Polytechnic Institute (SUNY Poly) senior Nikolas “Niko” Bardis isn’t one of them.

“I don’t think there was ever a point [in time] when I wanted to do anything besides make stuff,” said the Plattsburgh native and Mechanical Engineering Technology major. “I had an old notebook as a kid with ridiculous ideas and inventions I wanted to create.”

As part of an art project, one of Bardis’ first creations was a chair made from welded railroad ties.

“I’m a very visual person. I’m very good at imagining 3D objects, moving them around, so when someone asks me to design something, or there is an issue, I can pretty easily look at the situation and envision what’s going to work and what’s not,” Bardis explained. “I just kind of like that process. I think it’s a really cool and interesting challenge.”

After earning his Associate’s Degree at Clinton Community College, Bardis chose to further his education at SUNY Poly. It allowed him to be within a good distance of home, and after visiting the campus on Accepted Students Day and seeing the Wildcat Motorsports SAE Baja club, he was hooked.

Bardis has enjoyed the smaller class sizes at SUNY Poly, allowing for closer interaction and interesting discussions with professors. He also has enjoyed access to and learning how to operate various high-end equipment.

While many great inventions started with one person’s idea, through coursework and his involvement with Baja, one of the most important things Bardis has learned is the importance of being team-oriented.

“That’s really how the real world works,” said Bardis. “It’s never just you. It’s always a group of people working together. If there are issues within the team, the whole project winds up failing.”

Up until recently, Bardis served as the Baja club’s vice president, helping manage the team, making sure everyone had a project and stayed on task.

For their senior capstone project, Bardis and fellow seniors Sam Carlin and Zackery Kleist created a wood gasifier that converts biomass into combustible gas.

Bardis learned of the technology, which has been around for a long time, after watching a video online of someone creating a wood gasifier out of welded metal that was used to run a generator. The trio then got to work on making their own wood gasifier come to life.

“The document we used to build it had been around since just after World War II,” said Bardis. “Basically, the wood gasifier is a device that when you heat up organic matter, it causes it to rapidly decompose … speeding up that process. We designed ours to work with wood, but you can technically do it with any organic matter.”

Bardis explained that in their research they found that many companies have used this process in recycling. Instead of incinerating the garbage, they’d gasify it.

The process allows for more flexibility as it’s able to gasify items such as tires, computers, medical equipment, etc. and is also able to take any metal off of those items. If done correctly, syngas – a clear substance that looks like propane – is created. Syngas can be used to make fertilizers, hydrogen, liquid fuels like gasoline or potentially even jet and diesel fuel.

It’s also a carbon neutral process.

“There’s fewer impurities to it and you’re taking out a lot of the carcinogens and other crud in it. And it’s better for the environment,” said Bardis, “because if you put that garbage in a landfill, the greenhouse gases you get from it, like methane, are worse than if you burn it.”

After graduation, Bardis will be returning home to Plattsburgh. He’s been hired as a manufacturing process engineer at Schluter Systems, where he had previously interned.

“I learned a lot,” he said of his time at SUNY Poly. “I made several good friends and connections. I’m excited to see what the future holds and I feel like SUNY Poly has given me a good base to be successful.”