John Russo has always enjoyed working with his hands.

Combining that with a love of technology led John to study mechanical engineering technology at SUNY Polytechnic Institute in Utica, where he entered his senior year in Fall 2016. Along the way, John is taking full advantage of the real-world experiences available to him at SUNY Poly with a 10-week internship at Indium Corporation, a refiner, producer, and supplier of indium and indium compounds.

“I knew I wanted to do an internship to acquire new skills and have a hands-on chance to apply the education and knowledge I gained in school,” John says. “It definitely offers you some great experiences to talk about on your resume when applying for different jobs.”

In order to snag an internship with such a renowned industry leader as Indium, John made sure to do his homework first. He attended the annual Career and Graduate School Fair held at SUNY Poly each spring, and when he learned Indium had opportunities to intern, he was quick to refine his resume and cover letter. But it didn’t stop there, as John knows, showing a persistence that paid off – sending emails, making phone calls, and landing an in-person interview that led him to where he is today.

Throughout his internship at Indium, John has had the opportunity to work on a multitude of projects, including Surface Insulation Resistance (SIR) testing, which helps to characterize the printed circuit board (PCB) manufacturing and electronics assembly process residues and their impact on reliability.

“This is usually performed on industry standard test board coupons containing patterns, typically interlocking comb test patterns, designed for this testing purpose. The patterns are exposed to a high humidity environment which mobilizes any surface contaminants and reduces the insulation resistance of the test pattern.”

“This is usually performed on industry standard test board coupons containing patterns, typically interlocking comb test patterns, designed for this testing purpose. The patterns are exposed to a high humidity environment which mobilizes any surface contaminants and reduces the insulation resistance of the test pattern.”

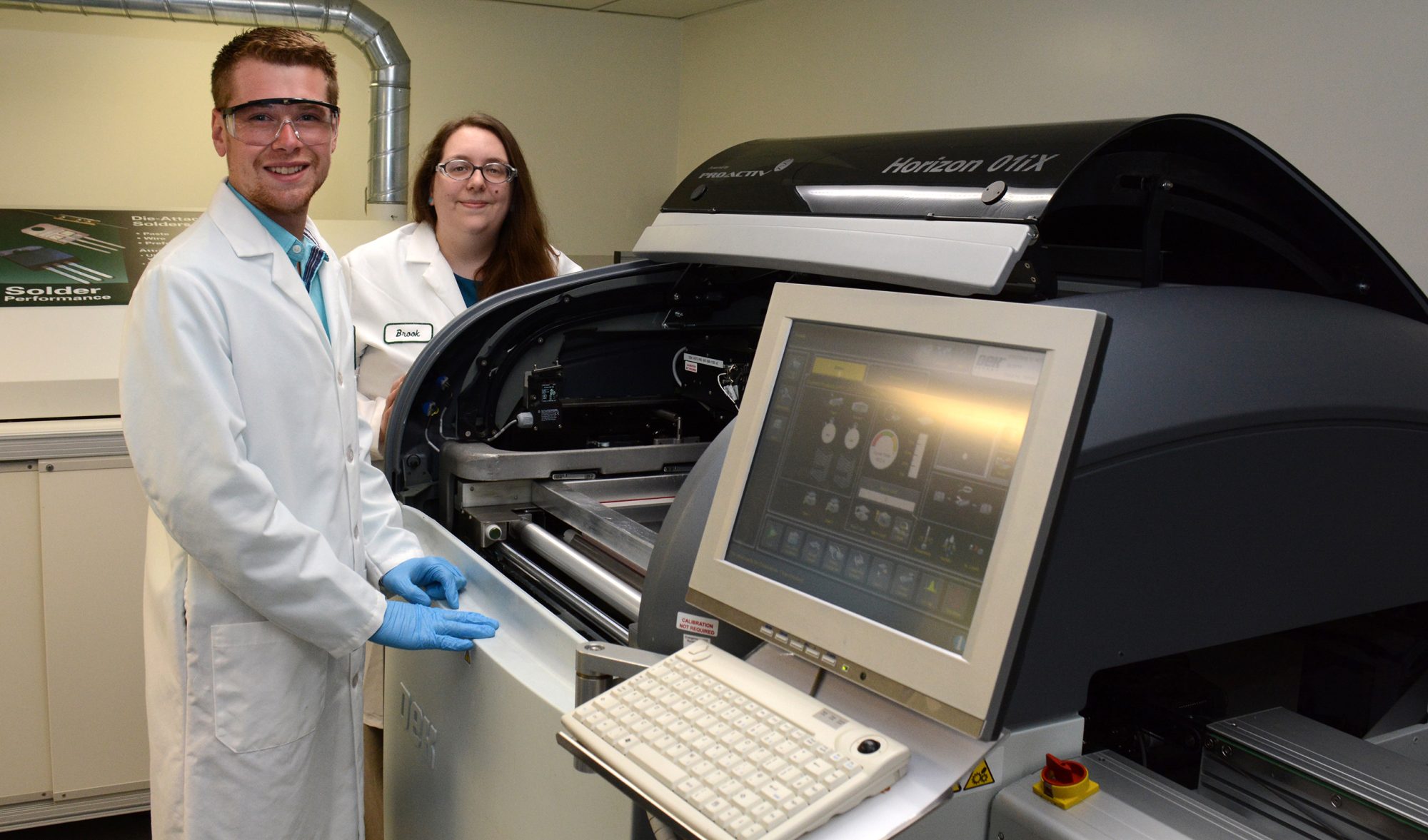

Along with that, John is also working on Surface Mount Technology printing of solder paste on PCBs.

“This allows us to test different types of paste and compare them to each other.” He describes how, “After going through the reflow oven the defects that can occur are pool wetting, bridging and graping; all of these can negatively impact the PCB.”

Understanding solder paste and its properties can be challenging, but it’s something that John has been quick to learn along the way.

“When examining different prints and looking at the different types of paste trying to find defects, it’s more a type of skill that comes with experience. My supervisors do everything they can to teach me; they know I am a fast learner and I am quickly expanding my knowledge in the field.”

It’s not just the hands-on experience at Indium that is making John’s internship worthwhile. It’s the experience and guidance of their expert staff who he’s working alongside every day.

“Brook Sandy-Smith, Eric Bastow, Maria Durham and Glen Thomas, they make me learn in a way which not only helps me improve my understanding of everything, but it gives me a real-world experience by having to make presentations in our weekly group meetings.”

They are experiences that John knows will serve him well when he graduates and heads out into the engineering field. But while he’s gaining new and exciting knowledge every day at his time with Indium, he notes that the foundation of knowledge that prepared him for his time there started with his time at SUNY Poly.

“As I told my supervisors, school is the number one thing on my list of priorities. The group projects, engineering courses, all the higher level English classes I’ve taken at SUNY Poly, it’s all helped me succeed in this internship.”

And as his internship experience draws to a close, John plans to continue working part-time at Indium Corporation while completing his bachelor’s degree at SUNY Poly and prepares for even greater experiences in the world ahead.